Vortex Flow Meter - IBR Approved Steam Flow Meter

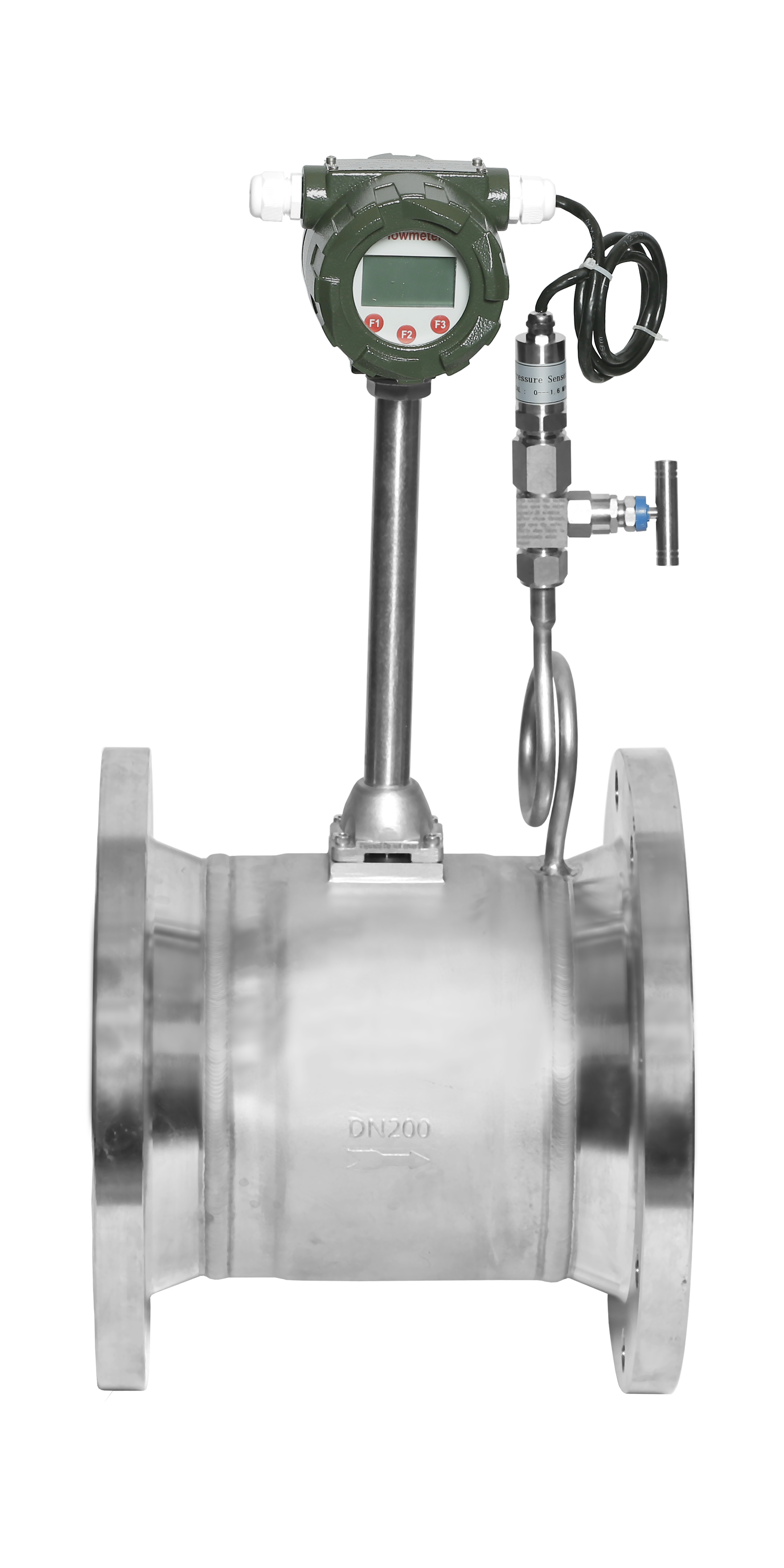

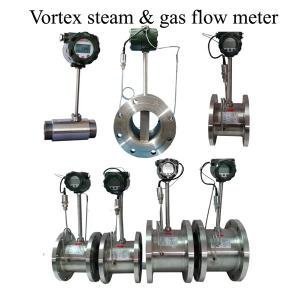

BROIL Vortex Flow Meter

BROIL Vortex Flow Meter is approved by the Indian Boiler

Regulation (IBR), the Directorate of Boiler, Government of India, for measuring

both steam and water in boiler applications. It operates based on the Karman

vortex street principle and is widely used in various industries including

petroleum, chemical, metallurgy, and heat supply.

Technical Specification:

- Process media: Gas, liquid, air, steam, vapor - With PRESSURE and TEMPERATURE Compensation

- Enclosure: flame proof to Gr iia,b and Intrinsically safe Ex Ia

- Accuracy: +/- 0.5% for liquid, 1% for gas and steam

- Repeatability: 0.2%

- Flow Range:

- Liquid: 0.4-7.0

m/s

- Gas: 4.0-60.0 m/s

- Steam: 5.0-70.0

m/s

- Maximum working pressure: 6 MPa

- Fluid & Ambient temperature: -40 to 350°C

- Connection: Thread (M/F) or flange

FOR HIGHLY CORROSIVE GAS AND LIQUID WE COSTUME DESIGN AS PER SUITABLE MOC PARTS LIKE PFA, PTFE LINED, HESTALLOY AND TENTALUM ETC

Product Feature

Display:

- Power voltage: 24 V DC TWO WIRE & 4 WIRE AND BATTERY : 3.3 V

- Display mode: Liquid Crystal Display (LCD) showing

instantaneous flow, cumulative flow, pressure, and temperature readings

- Cumulative flow: Automatically expands the display

precision and retains values even during power failures

- 3-wire pulse

- 2-wire 4 to 20 mA

- RS-485

- HART

Measuring Ranges for Liquid (Water):

- Flow rate: m3/hour

Measuring Ranges for Gas (Density: 1.12, Pressure: 1 bar):

- Flow rate: m3/hour

Measuring Ranges for Saturated Steam (Above 10 bar pressure,

contact the company):

- Flow rate: kg/hour and Other Unit Selectable

Product Features:

- Measuring ranges for Saturated Steam: Above 10 bar

pressure (contact the company)

Range:

- Liquid: 0.4-7.0 m/s

- Gas: 4.0-60.0 m/s

- Steam: 5.0-70.0 m/s

Product Appication

Product Applications:

- Pure Water?

- Fuel

- Air & Gas

- Steam

- Acid & Chemical

FOR HIGHLY CORROSIVE GAS AND LIQUID WE COSTUME DESIGN AS PER SUITABLE MOC PARTS LIKE PFA, PTFE LINED, HESTALLOY AND TENTALUM ETC